carrier splined to the main or converter out-put shaft (X). The planetary pinion gears also mesh with a sun gear (5) that contains a free wheeling unit.

As the first turbine is turned by the force of the spinning oil from the pump, this planetary gear assembly multiplies its propelling power resulting in a maximum multiplication of engine torque of 4.55 to 1 when selector lever is in Low setting.

As the oil leaves the first turbine during initial acceleration, the second turbine (6) and stator (7) redirects the oil to the pump. During this stage the first turbine is performing the torque multiplication function of the converter.

As the first turbine increases in speed, the second turbine also increases in speed. As engine and car speed step up, the second turbine begins to take over and drive the car. During this transition the direction of returning oil gradually shifts to the back side of the stator vanes instead of the front, causing the stator to free-wheel.

The two over-running clutches permit the stator and sun gear to free-wheel - independently. The second turbine then takes over completely.

At this point, Dynaflow acts as a fluid coupling transmitting power at a 1 to 1 ratio.

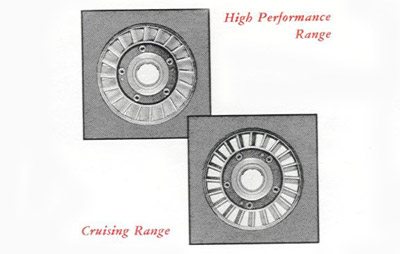

The 1955 Dynaflow stator (7, main illustration) has twenty propeller-like blades set on angle. Stator

blades are mounted on individual crank pins so that the "pitch" (angle of attack) may be rotated approximately 75 degrees. A stator piston linked to the throttle linkage through a control valve actuates the stator blades. Oil pressure moves the stator piston and the blades to low "pitch" (cruising range) or high "pitch" (high performance range).

Variable Pitch Dynaflow thus provides an economical "pitch" for all ordinary driving, and a performance "pitch" for the moments when you want extra-quick acceleration.